規格袋

規格袋

規格袋

規格袋

品名: 五金工具、零件袋

材質: PE一般透明夾鏈袋

尺寸範圍: 寬 85~ 400 mm

長 100~ 500 mm

厚0.055~0.12mm

包裝用途: 五金工具、零件

印刷顏色: 淺黃、灰、咖啡單面3色

條件: 1.難套色

2.夾鏈上中央打一洞

3.右上角打一洞

規格袋

規格袋

規格袋

品名: 通用袋

材質: PE一般透明夾鏈袋

尺寸範圍: 寬 50~ 170 mm

長 70~ 240 mm

厚 0.05~0.08 mm

包裝用途: 美容、通用包裝

印刷顏色: 紅、粉紅單面2色

條件: ?

規格袋規格袋

規格袋規格袋

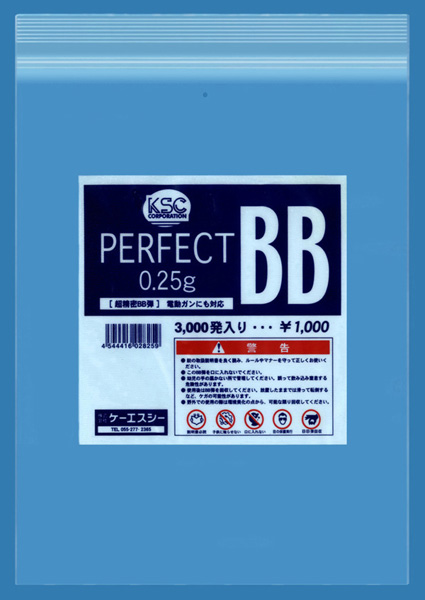

品名: BB彈袋

材質: PE一般透明夾鏈袋

尺寸範圍: 寬 100 ~ 350 mm

長 140 ~ 400 mm

厚 0.06 ~ 0.1 mm

包裝用途: BB彈

印刷顏色: 白、黑、紅單面3色

條件: 1.夾鏈下中央打一洞2m/m

2.難套色

規格袋

規格袋

規格袋

品名: 贈品袋

材質: PE一般透明夾鏈袋

尺寸範圍: 寬 140~ 450 mm

長 200~ 550 mm

厚 0.05~0.12 mm

包裝用途: 眼鏡、資料、贈品

印刷顏色: 黃、藍單面2色

條件: ?

規格袋

規格袋

規格袋

品名: BB彈袋

材質: PE一般透明夾鏈袋

尺寸範圍: 寬 100~ 350 mm

長 120~ 400 mm

厚 0.055~0.1 mm

包裝用途: BB彈

印刷顏色: 白、藍、黑單面3色

條件: 1. 夾鏈下中央打一洞

2.要套色

規格袋規格袋

規格袋規格袋

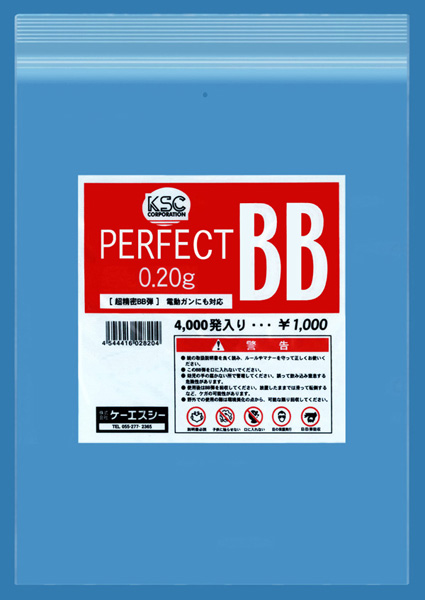

品名: BB彈袋

材質: PE一般透明夾鏈袋

尺寸範圍: 寬 120~ 350 mm

長 140 ~ 400 mm

厚 0.06 ~ 0.1 mm

包裝用途: BB彈

印刷顏色: 白、黑、紅單面3色

條件: 1.夾鏈下中央打一洞2m/m

2.難套色

規格袋是一種在尺寸、形狀、材質等方面有標準化要求的袋子,通常被用於包裝和運輸各種產品。規格袋的標準化要求可以確保袋子能夠更好地適應產品的包裝和運輸需要,從而提高產品的安全性、可靠性和效率。

規格袋的主要特點包括:

尺寸規格化:規格袋通常有標準化的尺寸要求,可以更好地適應不同尺寸產品的包裝和運輸需要。

材質規格化:規格袋通常有標準化的材質要求,可以更好地適應不同產品的特性和要求。

包裝效率:規格袋的標準化要求可以提高包裝和運輸的效率,從而節省時間和成本。

產品安全性:規格袋的標準化要求可以確保產品得到更好的保護和運輸安全。

規格袋通常被用於包裝和運輸各種產品,如食品、藥品、化妝品、文具、衣物等。不同行業和產品通常需要不同的規格袋,以滿足其特定的包裝和運輸需要。例如,食品行業通常需要使用食品級材料製成的規格袋,以確保食品安全和衛生。在醫藥行業中,規格袋通常需要具有特定的防潮、防靜電、防輻射等特性,以確保醫療用品的安全和有效性。在文具和衣物等行業中,規格袋通常需要具有透明度、防潮、耐用等特性,以便消費者可以看到產品的內容並保護產品的品質。由於規格袋的標準化要求和廣泛應用性,它們是各行各業中不可或缺的包裝和運輸工具